The company's mold factory has a professional R&D and manufacturing team for intelligent equipment and mold, a wealth of intelligent production equipment, and the ability to design and manufacture various types of intelligent fixtures and toolings like 2K tooling, in-mould assembly (IMA) tooling, IML tooling, optical guide tooling, gas-assisted tooling (grab handle), high gloss tooling (Rapid Heat Cycle Moulding), etc.

· High-speed milling mirror processing technology

· Manufacturing process specification design

· R&D technology of fully automatic/semi-automatic intelligent production equipment

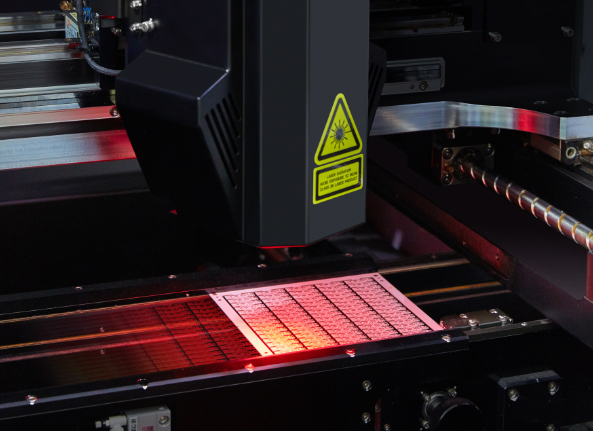

· R&D technology of fully automatic terminal testing equipment (cockpit functional parts/lighting parts)

Menu

Menu 中文

中文 English

English Deutsch

Deutsch 日本語

日本語